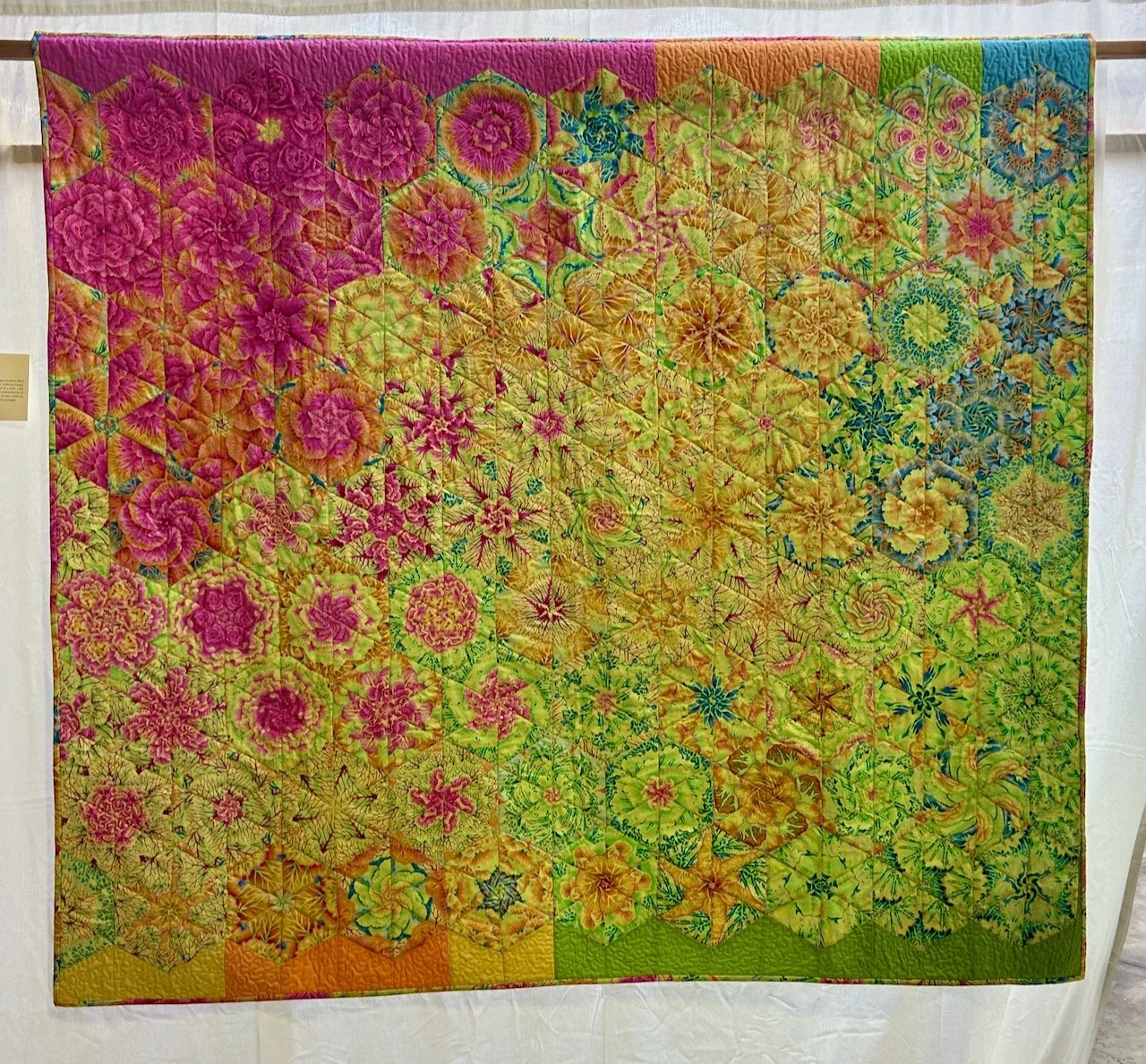

Back at the start of August my SIL and I headed off to the Festival of Quilts at the NEC - I’ve so many photos still to edit, and posts will follow but in short so many beautiful quilts! We’d booked on a workshop, and again there were so many to choose from, so in the end I left it up to my SIL to choose which one.

And she chose well, the kantha textured mini landscape workshop by Angela Daymond. I knew little about what we’d create, but I had been to one of Angela’s workshops before at the Stitch Festival in London back in 2023. And if you go back and read that post, I’m still curious as to how the notebook will turn out as I’ve not yet ‘cooked it’ - though, I do now at least have a saucepan which I could use for this, so maybe I’ll get around to that and show the results here - but don’t hold your breath!

I was looking forward to Angela’s workshop though and was hopeful that I’d stand more chance of completing the outputs from this one, given my increased opportunities and interest in hand stitching. And I was right, but first let me show you how I got on.

A kantha stitched landscape

Unusually I didn’t take any pictures while we were in the workshop, not even of Angela’s finished piece which was a bit daft. But then again it gave me free licence to do what I wanted, and interpret the written guidance shared on the day.

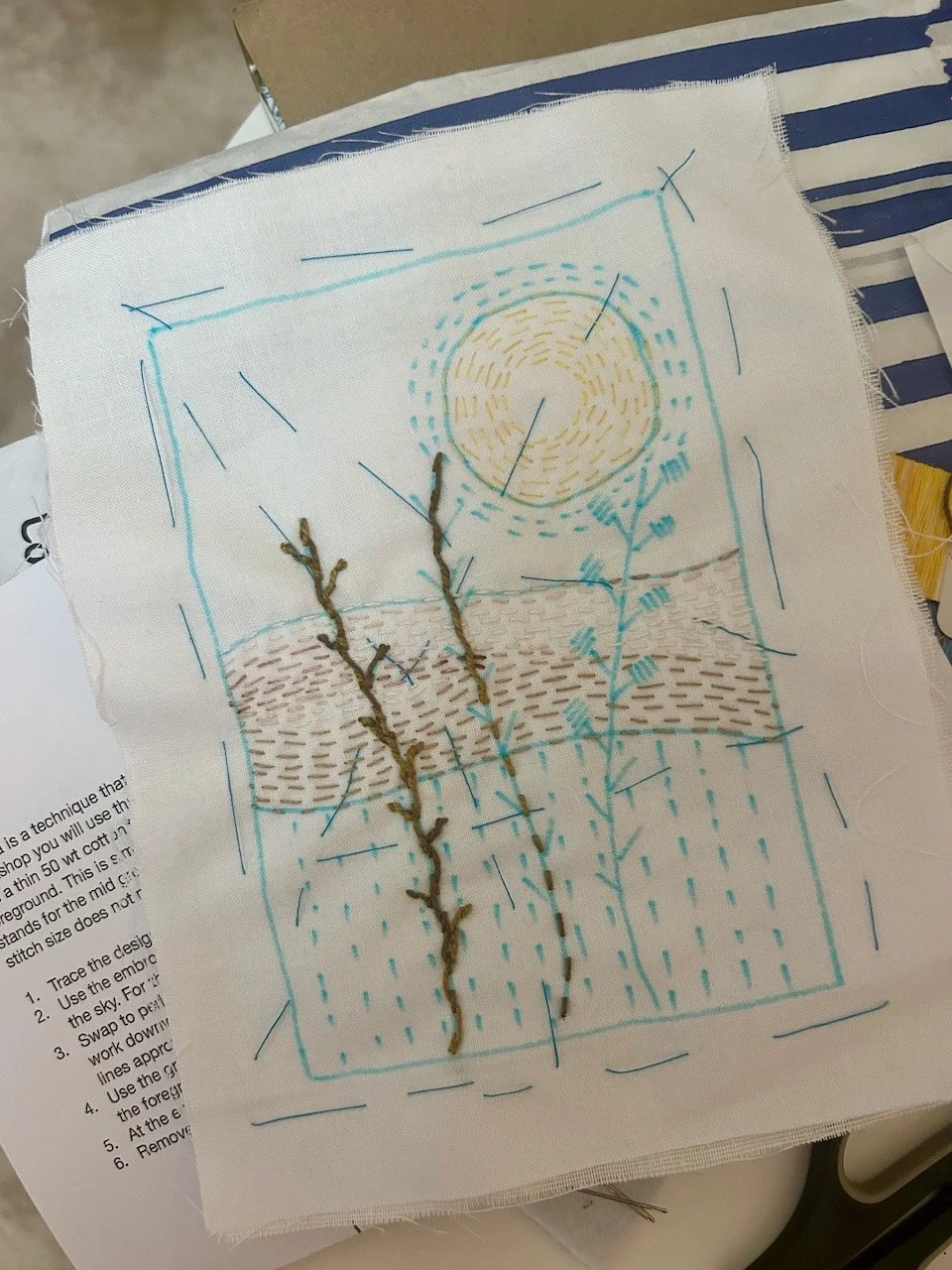

This was as far as I got in the workshop.

We’d started by tracing the design using a fabric marker pen and during the workshop Angela guided the group through the different stitching methods including tips for stitching circles, and sewing with the different thickness threads, as well as how to complete the weaved effect of the whipped running stitch on the stems.

I was keen to carry on and get this finished, so the week or so after the show this became my project.

I loved how it turned out, and I’m sure that each one from the workshop will look the same but different. I decided I needed to add some glitter to mine, on the sun and in the first few circles of the sky - and then well, in for a penny, in for a pound, onto some of the red berries too.

Angela had said that to remove the blue pen you just had to go for it, if you tried to spot remove the markings then it would likely show up elsewhere in the design. So there was nothing else for it, but to plunge this into water and under the running tap.

Miraculously it disappeared. Phew!

I left it to dry on a towel, and as it was drying I began to think what I’d do with it. I decided to frame it, and as luck would have it when we were in the framing shop getting the Vogue pictures framed, I spotted some small frames made from offcuts in the sale. By now I also knew that I wanted to do another one, so I picked up two frames - and added my landscape into the pale green frame.

Designing my own version, with a hare

I’d enjoyed the kantha landscape so much I decided I would do another picture to fill the second frame I’d bought. I knew I had some ‘hare’ stamps and thought one of those might work with a similar horizon as before. In the end I flipped the background and half-traced half-drew the hare in the bottom right corner.

Then I got sewing. I used the same yellow and blue threads from the workshop - there was (and still is) plenty left. But I decided on something different for the ‘land’ and for the hare itself. I had some crochet threads from mum and thought the neutral-green-pink reel would work for the land, but also added a thin darker grey thread to this, sewing with two threads, to give it some extra texture and to keep a consistent colour throughout both ‘land’ sections.

For the hare I used another variegated thread, this time ranging from brown through to bright pink. What do you mean, you’ve never seen a bright pink hare?! Me neither, but hey, I think there may be hares out there wishing they were pink!

Once again the fabric marker pen washed out easily, and revealed the end design.

That too has been framed, this one got the gold frame - but both are now in our spare bedrooms on two of the four fabulous bedside tables, and they look great. I’ve plans for something slightly different on the two bedside tables which remain empty, but that idea yet to be started, so it may yet turn up on a ‘future stitching project’ list at some point. But in the meantime I’m going to enjoy these, and I hope our guests will too.